A Lighthouse of sustainability: How Kusters Calico drives the energy transition forward

In an era where sustainable business practices are no longer optional but a necessity, Kusters Calico Machinery Pvt Ltd in Vadodara, India, impressively demonstrates what is possible when commitment meets innovation. As part of the Jagenberg Group, Kusters Calico sets a strong example for industrial sustainability, paving the way for a greener future.

A major step towards net-zero energy

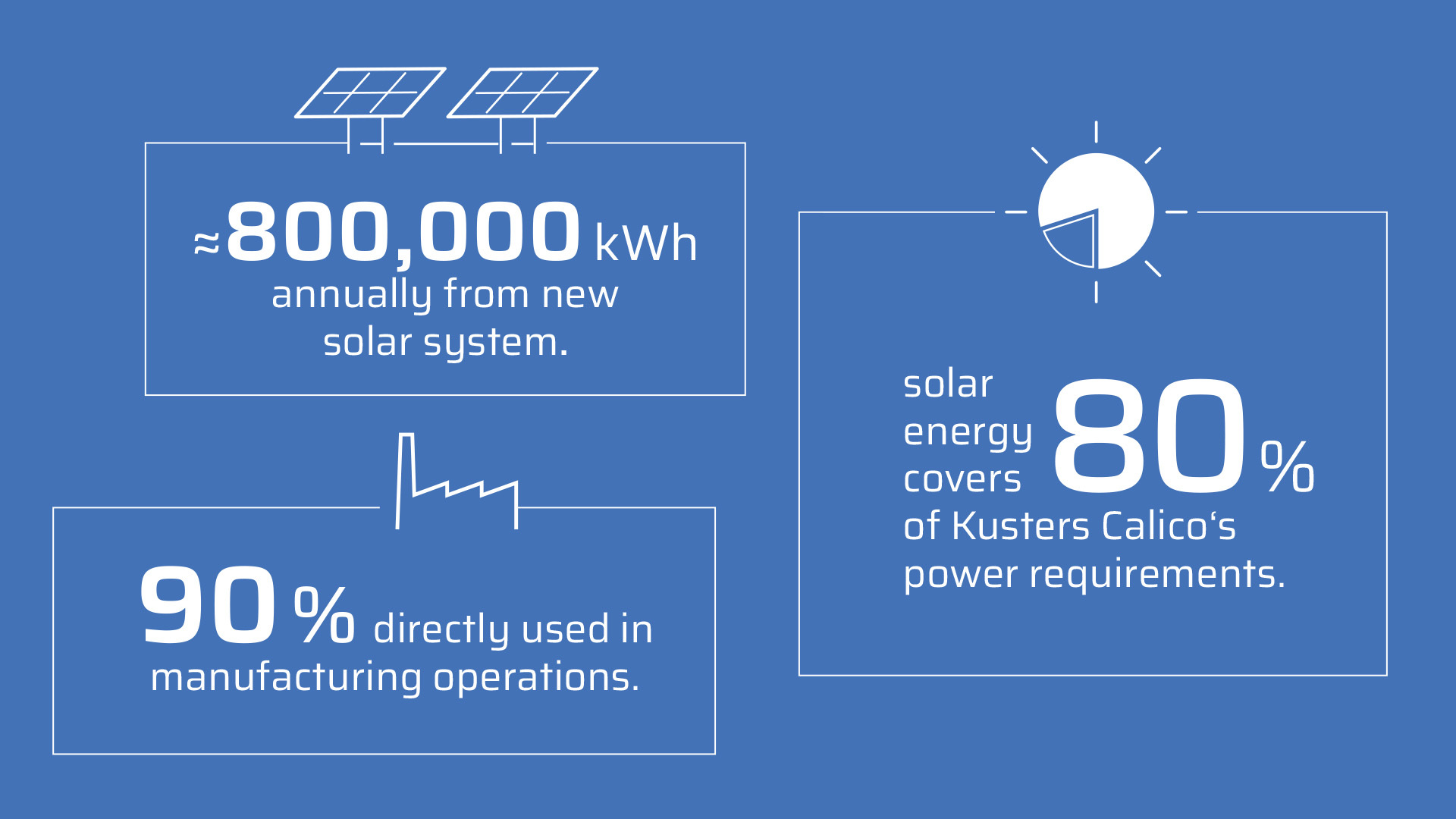

Kusters Calico recently commissioned a state-of-the-art 500 kW rooftop solar power system – a significant milestone on its journey towards net-zero energy consumption. This impressive system, installed on the rooftops of their production facilities, generates around 800,000 kWh annually, covering 80% of Kusters Calico's power requirements. Over 90% of the generated electricity is directly used in manufacturing operations, while excess energy on non-working days is sent back to the grid, earning energy credits.

Sushil Verma, Managing Director at Kusters Calico and one of the key figures behind this green transformation, emphasizes: "The planning took about six months and installation around eight weeks. We had to overcome structural challenges, ensure compliance, and manage the transition with minimal disruption but the results speak for themselves.“ The new system reduces CO2 emissions by approximately 560 tons per year, which marks a significant contribution to climate protection.

Sustainability based on conviction

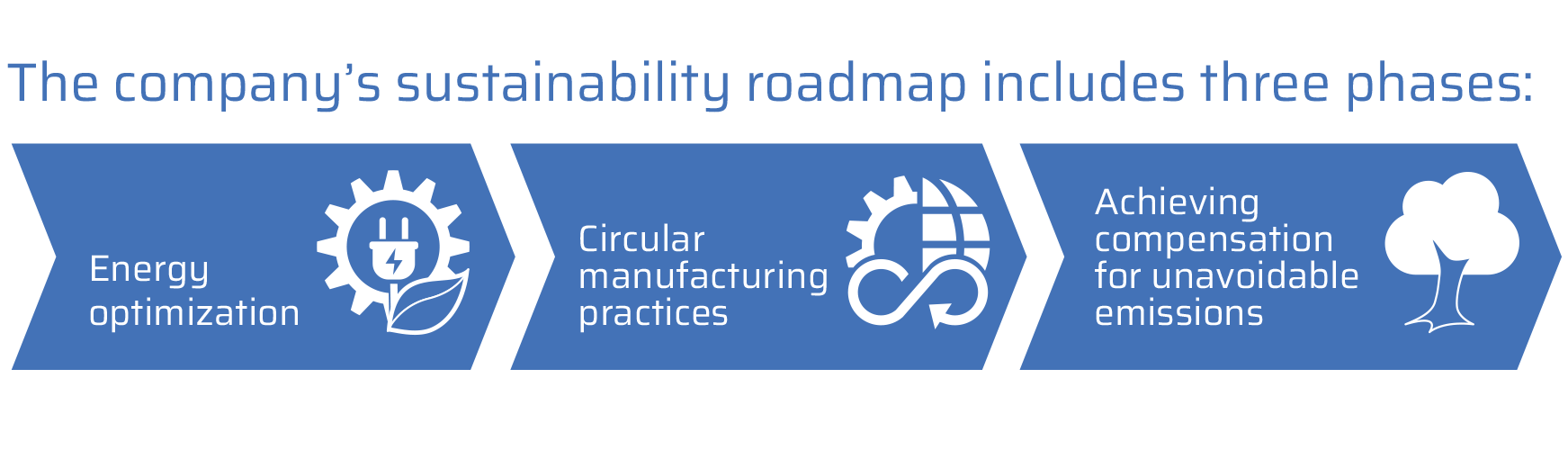

For Kusters Calico, however, this step is just one part of a larger sustainability roadmap. "Sustainability has always been in our DNA," Sushil Verma explains. "We started years ago with LED lighting and a smaller 40 kW solar installation. This latest step is the most ambitious yet, and it's only the beginning".

Kusters Calico's efforts extend well beyond solar panels. The company actively applies circular economy principles and implements energy efficiency upgrades across all operations.

These include:

- The reuse of wooden pallets and reducing packaging waste.

- The replacement of overhead cranes and shop-floor fans with energy-efficient alternatives.

- The installation of transparent roofing sheets to maximize natural light.

- The use of trolleys for material movement to reduce crane usage and power demand.

"We're aligning every part of our business – from manufacturing to logistics – with our green goals," says Sushil Verma.

Technology and transparency for a sustainable future

The solar system utilizes high-efficiency monocrystalline PV panels, smart inverters, and advanced monitoring systems for real-time tracking of performance and savings. A digital dashboard provides daily insights into power generation, efficiency, and system health. With more rooftop space available, Kusters Calico is open to future expansion as energy needs increase.

The solar initiative has sparked genuine excitement among employees, many of whom feel proud to work at a company actively investing in the planet's future. The local community, too, has responded positively. "We communicate our sustainability efforts through internal workshops, Jagenberg Group reporting, and a dedicated section on our website," Sushil Verma notes.

“It's important people understand this is not just about cost savings, it's about responsibility.”

Sushil Verma,

managing director Kusters Calico Machinery Pvt Ltd

Overcoming challenges, driving change

No green journey is without its hurdles. For Kusters Calico, energy storage remains a challenge, as battery systems are still costly. Aligning suppliers with sustainability goals is also a work in progress, which the company is committed to tackling.

Future projects include heat recovery systems, high-efficiency motors and drives, reduced water consumption technologies, and continued investment in green infrastructure.

Sushil Verma and his team at Kusters Calico are not just proud of what they have built. They are inspired by what this step forward represents. "We're not just making machines – we're shaping a cleaner, smarter future. That's a legacy we can all be proud of," Sushil Verma concludes.

As part of the Jagenberg Group, Kusters Calico aims to be a role model, sharing best practices and encouraging peers to adopt cleaner technologies and standards. Kusters Calico's journey is a blueprint for what industrial manufacturers can achieve when sustainability is not a side project, but a core business strategy. It is proof that with vision, planning, and commitment, clean manufacturing is not just possible – it is powerful.